TURNKEY® Rhino

HAMMERLESS Teeth and adapters

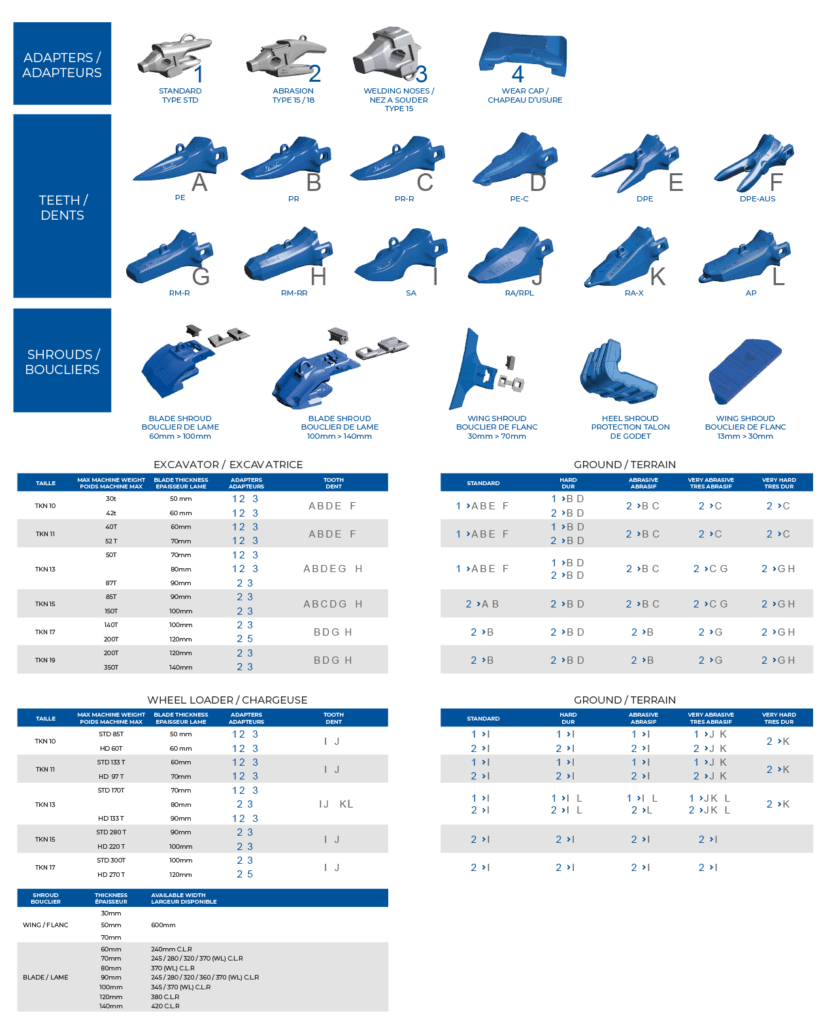

Discover our products sheets & adapters & teeth Turnkey® Rhino !

Bucket shrouds

Discover our products sheets dedicated to heel, side, & blade shrouds Turnkey® Rhino !

Discover TURNKEY® Rhino tips

Ground attack products dedicated to the construction and public works sector !

Discover TURNKEY® Rhino adapters

TURNKEY ® adapters are made of high-tolerance, resilient steel for optimized core welding

The stabilizing flats combined with the facets of the nose reduce the stresses on the keying, thus allowing an optimal clamping of the tooth on its support.

We can offer you three versions of adapters, two adapters with a wear cap for excavators and wheel loaders, and a third adapter called Standard without wear cap.

Discover TURNKEY® Rhino shrouds

Protect your blades, sides and heels of your buckets with our Turnkey® Rhino shields!

TURNKEY® Rhino's recommendation

Discover our equipment recommendations to optimize the performance & longevity of your ground attack tools

Facts et figures TURNKEY®

At the request of customers using our products in quarries, and for reasons of safety and speed of maintenance, Feurst has developed from 2013 the Turnkey® teeth and adapters which allow easy, secure and quick assembly and disassembly of the tooth and shrouds (blade & flanks) on their support.

- – The nose is robust, reliable and innovative.

- – Its complex shapes guarantee a perfect stability that reduces the movement of the tooth during the efforts related to the operation.

THE TURNKEY® LOCKING DEVICE IS A NEW HORIZONTAL, ROTATING AND ECCENTRIC SYSTEM FOR RECOVERING GAP.

Turnkey® locking has several special features:

- The forged PIN is held tight

- Its 180° locking is validated by an audible “click”. The operator is thus reassured that the key is properly locked.

- After manual unlocking of 180°, the pin is extracted without a hammer.

- The plug is water and dust proof. The fine dust will never clog the entire locking system.

- The two protection caps (right side and left side) participate in the sealing of the system and ensure easy access for removal.

Other features:

- The patented Turnkey® system has a reversible, stable and easily removable wear cap.

THE ADVANTAGES OF TURNKEY® TEETH

- A reliable system which allows a very high level of comfort during assembly and disassembly

- A new nose shape that offers greater resistance to wear

- Via this new Turnkey® system, Feurst® assures its users of a 50% increase in the life of their buckets.

- Constant compression: dust do not insert inside the system

- Motionlessness of the Turnkey® tooth on the adaptor: there is therefore less vibration and less shock

- An audible « click » indicates that the locking has been successfully completed

- All tooth sizes are available

- Availability in stock

- French manufacture

– For the product range: 300 references to cover all applications

– For the productivity gain demonstrated with +30% wear ratio

– For the speed and safety of operations

– For the comfort of the user and the machine: fuel savings of 8% on average, and less effort on the mechanical and hydraulic systems.

To develop the Turnkey® system, Feurst® relied on a wide range of existing products and more particularly on elements that have proven themselves:

- – A recognized metallurgical process

- – The concept of gap retention locking system

- – The bi-fitting geometry

- – A reversible adaptor wear cap